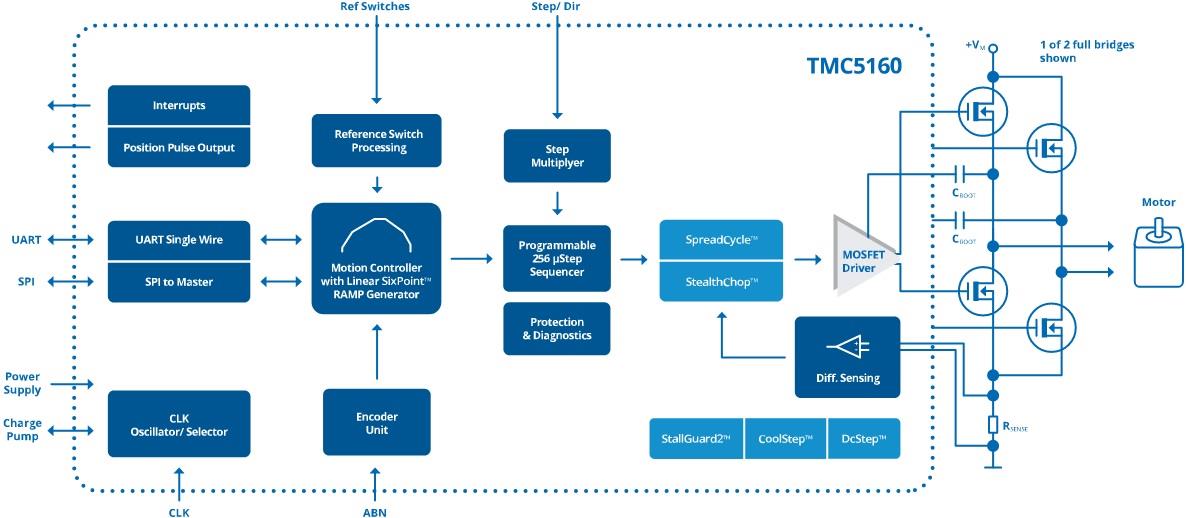

ADI Trinamic TMC5160 Motor Controller & Driver ICs

Analog Devices TMC5160 Motor Controller and Driver ICs are universal high voltage controllers/drivers for two-phase bipolar stepper motors with serial communication interfaces. These driver ICs combine a flexible ramp generator for automatic target positioning with the most advanced stepper motor drivers. The TMC5160 motor drivers feature 20A coil current (external MOSFETs) and can realize highly dynamic high-torque drives using external transistors. These motor controller drivers exhibit 256 micro-steps per full step resolution, 8VDC to 60VDC voltage range, and are available in a small form factor TQFP48 or QFN-56 packages.The TMC5160 motor controller and driver ICs incorporate proprietary MicroPlyer™, CoolStep™, SpreadCycle™, StallGuard2™, and StealthChop2™ technologies to provide high-integration, high energy efficiency, and cost-effective solutions. Typical applications include robotics and industrial drives, high-speed 3D printers, office-automation, factory and lab automation, textiles sewing machines, CCTVs, security, ATMs, liquid handling, and packing machines.

Features

- 2-phase stepper motors with up to 20A coil current (external MOSFETs)

- STEP/DIR interface with a micro-step interpolation

- Motion controller with SixPoint™ ramp

- SPI and single wire UART

- 8VDC to 60VDC voltage range

- Encoder interface and 2x reference switch input

- High resolution of 256 micro-steps per full step

- Resonance dampening for mid-range resonances

- Passive braking and freewheeling mode

- Full protection and diagnostics

- Compact TQFP-48 (7mm x 7mm) or QFN-56 (8mm x 8mm) package

- Key technologies:

- StealthChop2™

- No noise high-precision chopper algorithm for inaudible motion and inaudible standstill of the motor

- MicroPlyer™

- Microstep interpolator for obtaining full 256 micro-step smoothness with lower resolution step inputs starting from full-step

- SpreadCycle™

- High-precision, low noise, low resonance, and low vibration chopper algorithm for highly dynamic motion and the absolutely clean current wave

- StallGuard4™

- Sensorless stall detection and mechanical load measurement

- CoolStep™

- Load-adaptive current control reducing energy consumption by as much as 75%

- DcStep™

- Load dependent speed control (motor moves as fast as possible and never loses a step)

- StealthChop2™

Applications

- Robotics and industrial drives

- High-speed 3D printers

- Packing machines

- Office and home automation

- Factory and lab automation

- Textiles and sewing machines

- Liquid handling

- CCTVs and security

- ATMs and cash recycler

- Medical

- Pumps and valves

Block Diagram

Videos

Published: 2020-07-15

| Updated: 2024-04-05